Oil water separators are helpful for isolating oil and water so as to keep contamination out of the biological system. There are bunches of modern procedures that required the blending of oil with water and before the water can be discharged go into nature, the oil must be appropriately dispensed with. There are various details of oil water separators and some of them will be treated right now.

Downpour Water Separators

At the point when downpour washes across roads and parking areas, oil from defective motors is gotten and the water enters the tempest channel framework. A separator is set before the outlet to forestall the oil loaded water from being discharged to the earth. It is prescribed by the University of Mississippi that 20 square feet of the surface region in the separator is perfect for each 10,000 square feet of the seepage region. For instance, a parking area estimating 100 feet by 100 feet has 10,000 square feet of surface territory and requires a separator tank’s surface size of 5-feet in length and 4-feet wide.

Marine Separators

A bilge water of a boat gathers oil from motors and other break overflow. This water must be released into the sea and if a separator can’t, all the oil would be released also which is perilous for marine life. As per the Massachusetts Maritime Academy, the boat’s bilge water release can contain all things considered 15 sections for every million PPM of oil. For example, in one million gallons of water, just 15 gallons are permitted to be oil. Separators are planned by engineers utilizing various techniques like screen sifting. It is significant for the 15 PPM objective to be accomplished before any bilge water release happens.

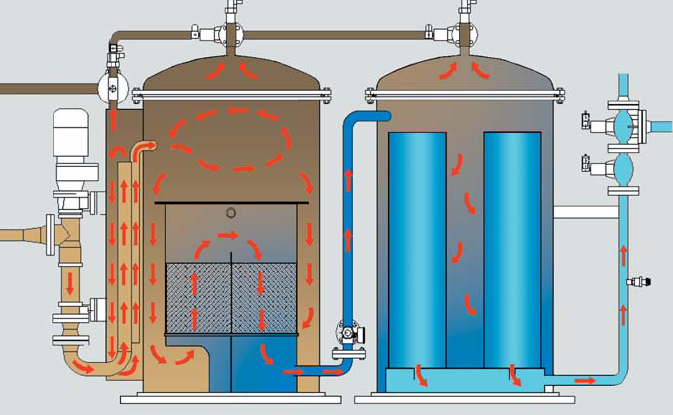

Diesel Engine Fuel Separator

On the off chance that any water is in the diesel fuel, the motor will won’t run. Fragile interior parts will be annihilated on the grounds that rust will set in. Since water goes into the fuel framework through common dampness in the air consolidating into the fuel, all diesel motors accompany Oil Water Separators in the fuel frameworks so as to evacuate all the water totally. Separators are structured by architects to work through different techniques yet they all follow the rule that oil ascends to the highest point of water. There are gulfs and outlets at the highest point of the separators and at the base are nozzles. The nozzle should be opened consistently by a professional so as to deplete off the water.